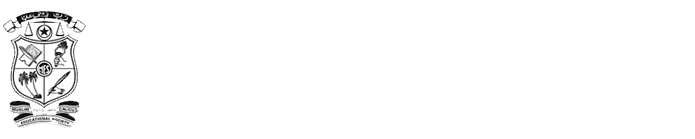

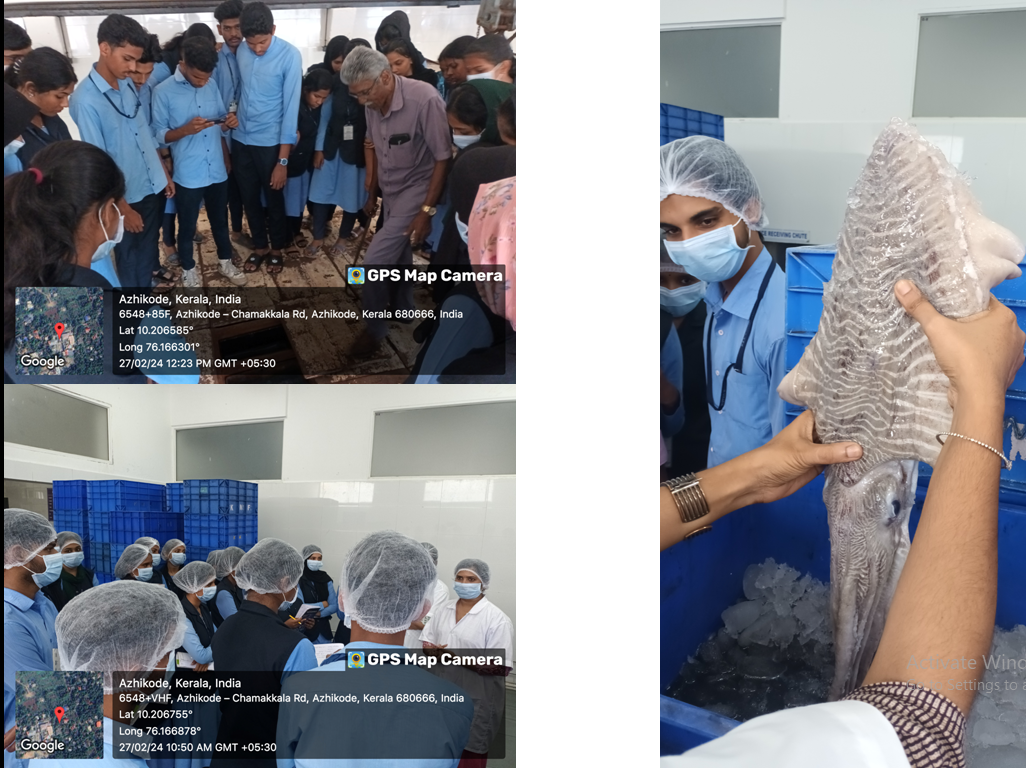

On 27th of February 2024, the students of S6 Aquaculture (44 students – 12 Boys and 32 Girls) went for an Industrial visit to KM Fisheries, which is a seafood Processing and exporting plant, located at Azhikode. KM Fisheries is one of the forefront marine exporters in Kerala, with a good reputation for the quality of their Products. The company has European Union approval and HACCP certification. The students and faculties reached at the Company at 10 am in College bus. The students followed the instructions given by the staff of KM fisheries to keep up hygiene by wearing head gear, masks, gloves, and gumboots are dipped in the chlorine at 20 and 100ppm respectively. The quality controller of the plant guided us to the raw material receiving rooms, where the raw material for the plant was collected. The major raw materials certified and received were cuttlefish, squid material, Indian oil sardine, octopus, shrimp, and tuna. Then they moved on to the processing room. The raw materials were graded and cleared according to their size. And then we moved to the air blast freezer and tunnel freezer and their working procedure was explained by the Quality Controller that is, Air blast freezing is carried out by passing a continuous stream of cold air over the product. Air blast freezer is a versatile type of freezer since it is easy to freeze irregularly shaped, different sized, and non-deformable products in this equipment. In the Tunnel freezer, The product moves through the machine on a conveyor and is led past axial fans. The fans blow the air through an evaporator generating an air temperature of below -30°c. A quick freezing with a product temperature down to -18°c is achieved with this IQF tunnel freezer. Then we entered the storage room, where the processed items were frozen and stored. Individual quick freezing was employed to maintain its freshness, and quality and also to minimize drip loss by the sea foods are individually frozen. The students were then guided to Microbiology lab where the products were tested for quality assurance. It is constructed in a unidirectional flow to avoid cross-contamination, the plant may contain separate areas like the media preparation room, Sterilization room, distillation unit, incubation room, inoculation room, and discarding room. The procedures were explained by the lab operator, the plant had a well-controlled block ice production unit. After the visit to the KM fisheries, the students had a thorough knowledge of the workings of a seafood Processing Plant. We are thankful for the authorities and staff, Mr.Shareef, Miss. Athira Miss.Shameera and Miss. Devika for their collaboration and also relieved for spending their valuable time with them.